By Admin

By Admin

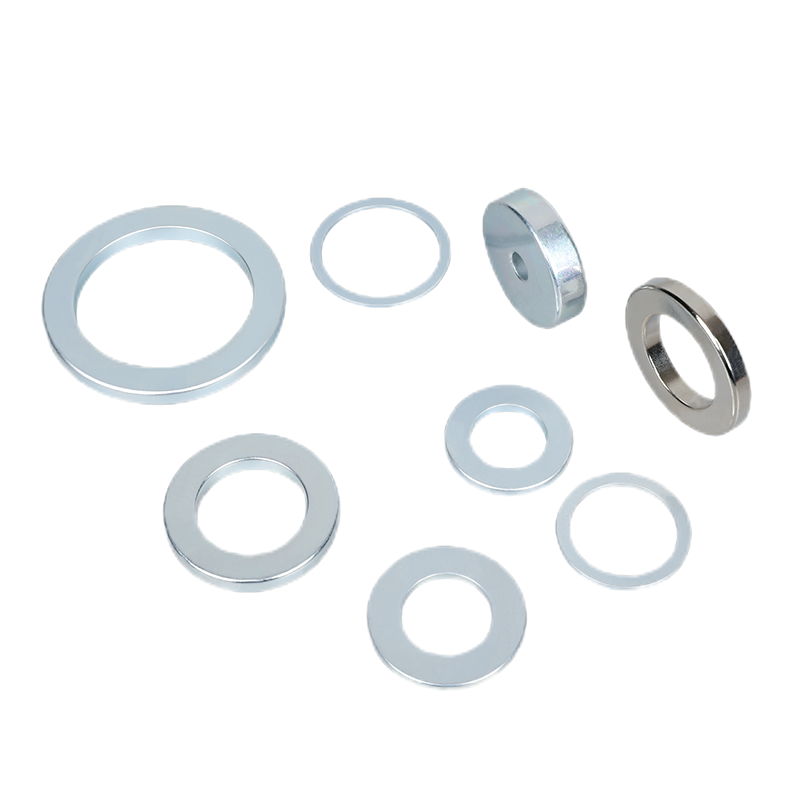

Mud recovery and utilization is an innovative technology aimed at addressing the large amount of mud waste generated during the production of neodymium iron boron. In traditional practices, mud waste is often seen as a disposal material that requires treatment and disposal. However, Zhejiang Zhongke Magnetic Industry Co., Ltd. recognizes the valuable magnetic materials contained in these wastes and has developed an efficient mud recovery and utilization technology.

The core of this technology lies in the effective separation and recovery of magnetic materials from the mud. Through a series of precise processing steps, including grinding, screening, and magnetic separation, the magnetic materials in the mud can be separated from other impurities. This separation technique is highly efficient and allows for the extraction of magnetic materials, enabling their full utilization.

The application of mud recovery and utilization technology brings many benefits. Firstly, by recycling the magnetic materials in the mud, the demand for raw materials can be reduced. This means that the amount of raw materials required in the neodymium iron boron production process can be decreased, thereby reducing resource consumption and mining pressure.

Secondly, mud recovery and utilization technology can also reduce environmental pollution. In traditional treatment methods, the discarded mud waste is usually disposed of through landfilling or incineration, which generates a large amount of waste gas and wastewater, causing serious environmental pollution. By recycling the magnetic materials in the mud, the generation of these pollutants can be avoided, effectively protecting the environment.

Furthermore, mud recovery and utilization technology can bring economic benefits. By recycling the magnetic materials in the mud, they can be sold as recycled resources or applied in other industries, resulting in economic gains. At the same time, the cost of waste treatment is reduced, further improving the efficiency of the enterprise.

In summary, the development and application of mud recovery and utilization technology have brought about significant changes in the neodymium iron boron production process. It not only reduces the demand for raw materials, minimizes resource waste and environmental pollution, but also brings economic benefits. The successful application of this technology not only promotes the sustainable development of the neodymium iron boron industry but also provides valuable reference for the recycling and utilization of waste in other industries.

Zhejiang Zhongke Magnetic Industry Co., Ltd. is a company dedicated to the research, production, and sales of magnets. Zhongke has been actively promoting sustainable development and environmental protection in the green, low-carbon industry.

Mud recycling and utilization: During the neodymium magnets production process, a large amount of mud waste is generated, and the conventional approach is to dispose of this waste. However, Zhejiang Zhongke Magnetic Industry Co., Ltd. recognized the value of magnetic materials present in the mud waste and developed an efficient mud recycling and utilization technology. This technology effectively separates and recovers the magnetic materials from the mud waste, reducing the need for raw materials and minimizing resource waste and environmental pollution.

Energy conservation and emission reduction: Zhejiang Zhongke Magnetic Industry Co., Ltd. focuses on energy conservation and emission reduction in the neodymium magnents production process. Zhongke has introduced advanced production equipment and processes, optimizing process flows and control systems to achieve efficient energy utilization. Additionally, Zhongke has adopted clean energy sources such as solar to replace traditional energy sources, reducing the emission of carbon dioxide and other harmful gases.

Wastewater treatment: The neodymium magnets production process generates a large amount of wastewater containing pollutants such as heavy metals and organic substances. Zhejiang Zhongke Magnetic Industry Co., Ltd. has established a comprehensive wastewater treatment system, employing physical, chemical, and biological treatments to purify the wastewater and ensure compliance with national and local environmental standards.

Gas emission treatment: The waste gases produced during the neodymium iron boron production process contain harmful substances such as ammonia and hydrogen sulfide. To reduce air pollution, Zhejiang Zhongke Magnetic Industry Co., Ltd. has implemented various measures for gas emission treatment.Zhongke has introduced advanced gas treatment equipment such as dust collectors and desulfurization devices, effectively removing pollutants from the waste gases and protecting the air quality in the surrounding environment.

Resource recycling: Zhejiang Zhongke Magnetic Industry Co., Ltd. emphasizes the recycling of resources. They classify and recycle waste products and production waste. By dismantling and reprocessing discarded products, valuable magnetic materials and other recyclable substances can be extracted, reducing the demand for raw materials and achieving sustainable resource utilization.

In conclusion, Zhejiang Zhongke Magnetic Industry Co., Ltd. has achieved significant results in the green, low-carbon industry. Through measures such as mud recycling and utilization, energy conservation and emission reduction, wastewater treatment, gas emission treatment, and resource recycling, the company has effectively reduced its environmental impact, protected the ecological environment, and made positive contributions to sustainable development.