Description:

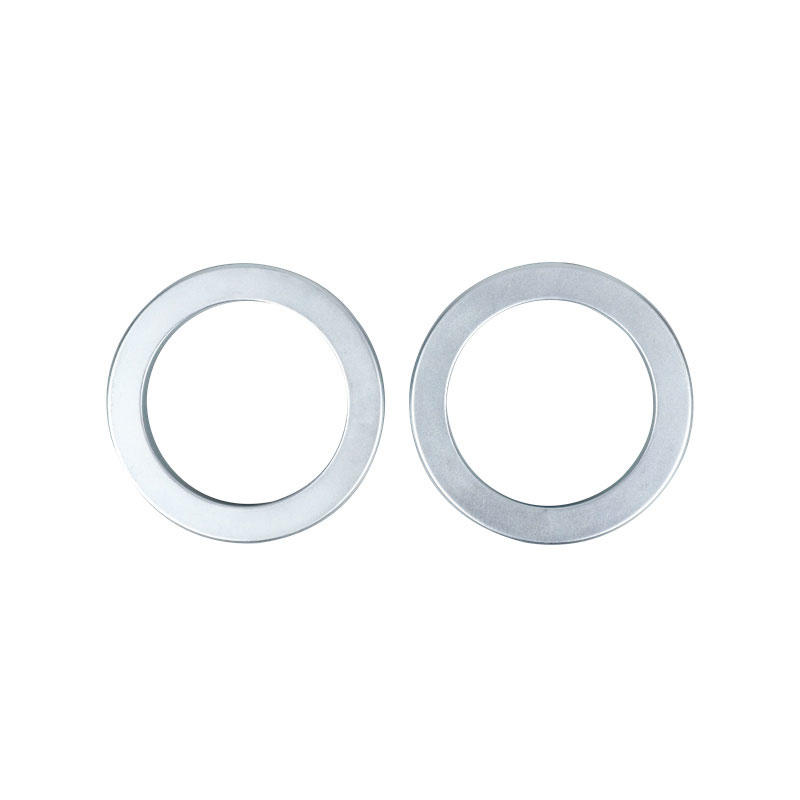

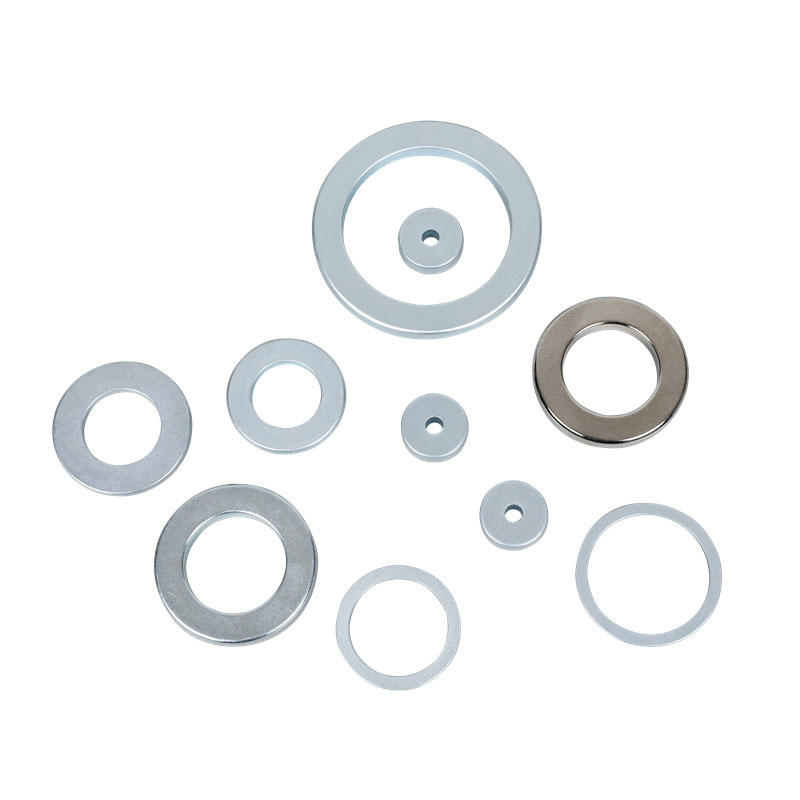

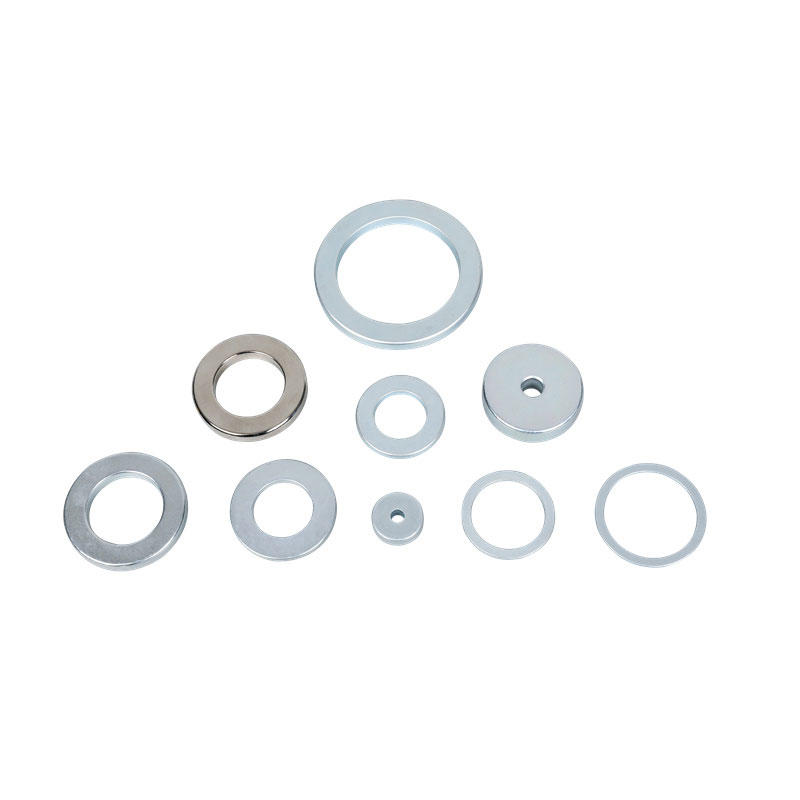

Applications of NdFeB Ring-Neodymium Ring magnets are used specifically for loudspeaker systems, hard disk drives, audio equipment such as microphones, acoustic pick-ups, headphones and loudspeakers, Dentures, Magnetically coupled pumps, Door catches, Motors and generators, Jewellery, Bearings.

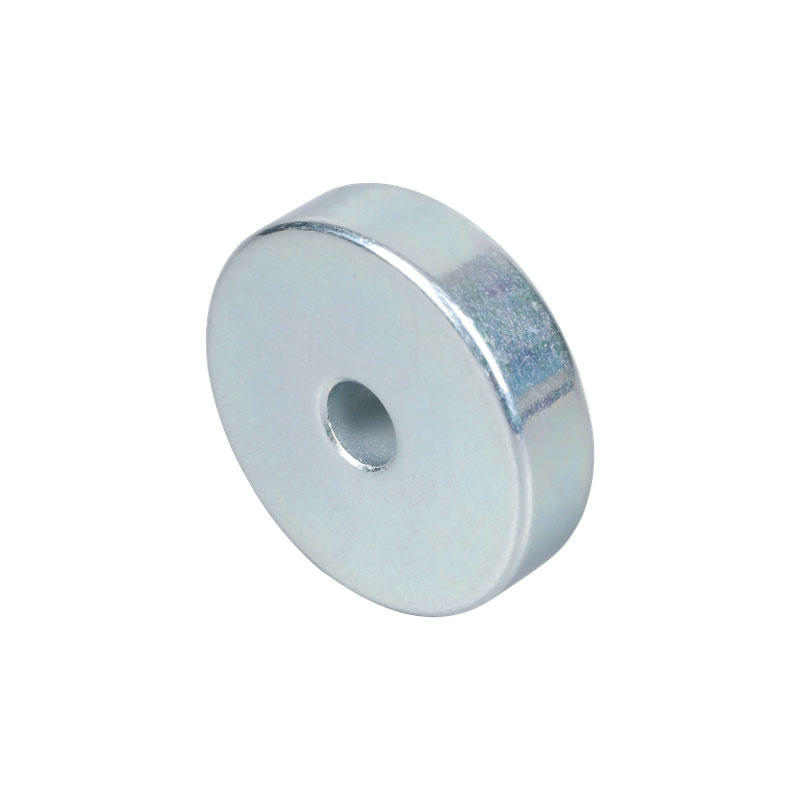

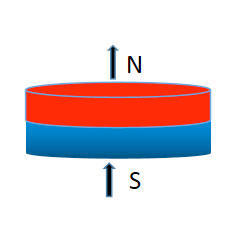

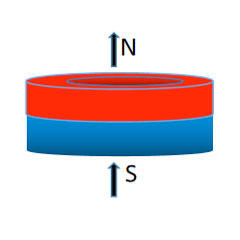

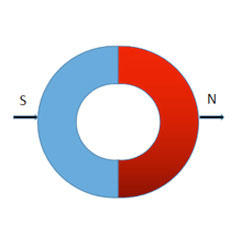

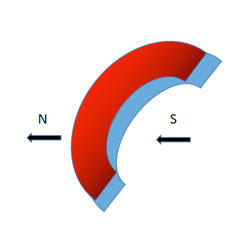

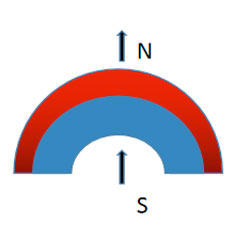

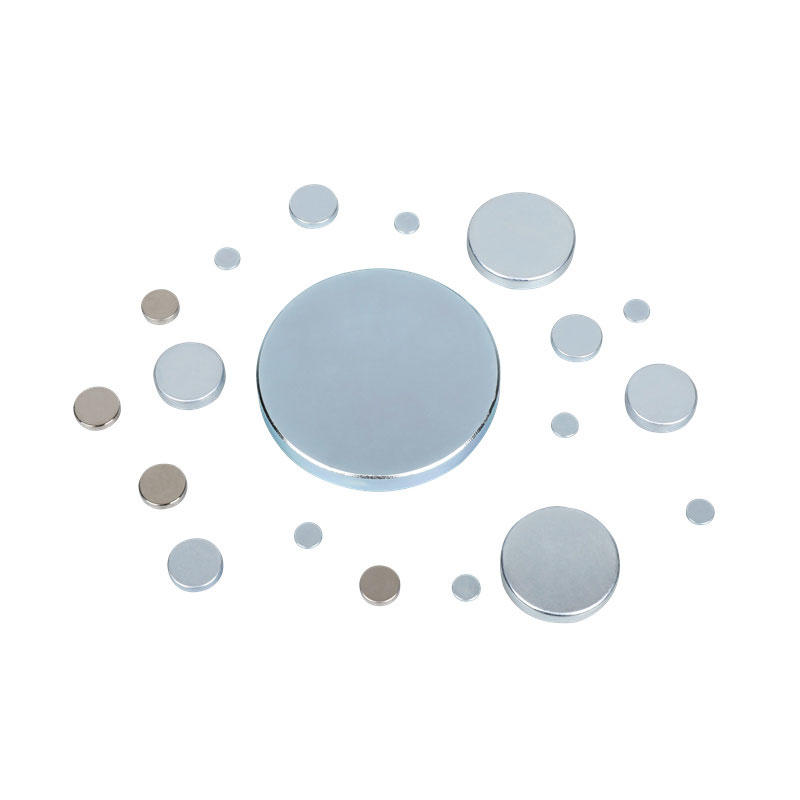

In speakers, NdFeB magnets are used in the form of a circular disc or a ring-shaped magnet. These magnets have a strong magnetic field, which helps to produce high-quality sound with excellent clarity and precision. The circular disc-shaped magnet is widely used in small to medium-sized speakers, whereas the ring-shaped magnet is suitable for larger speakers with higher power requirements. The advantage of using NdFeB magnets in speakers is that they are lightweight and compact, making them ideal for portable and space-constrained devices. However, the disadvantage is that these magnets are brittle and can crack or break if exposed to high impact or stress.

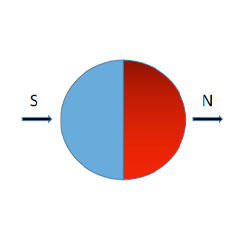

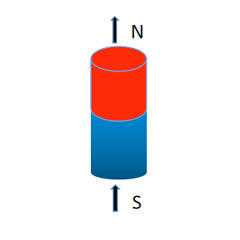

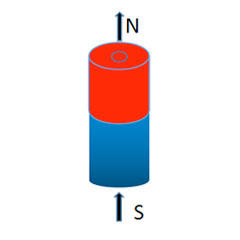

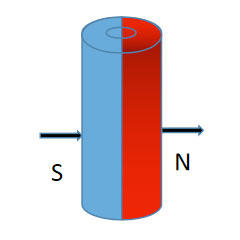

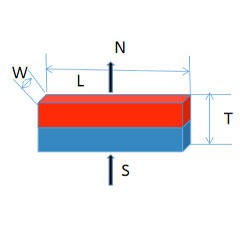

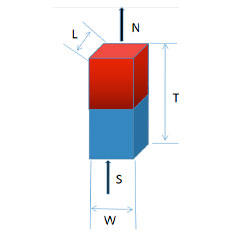

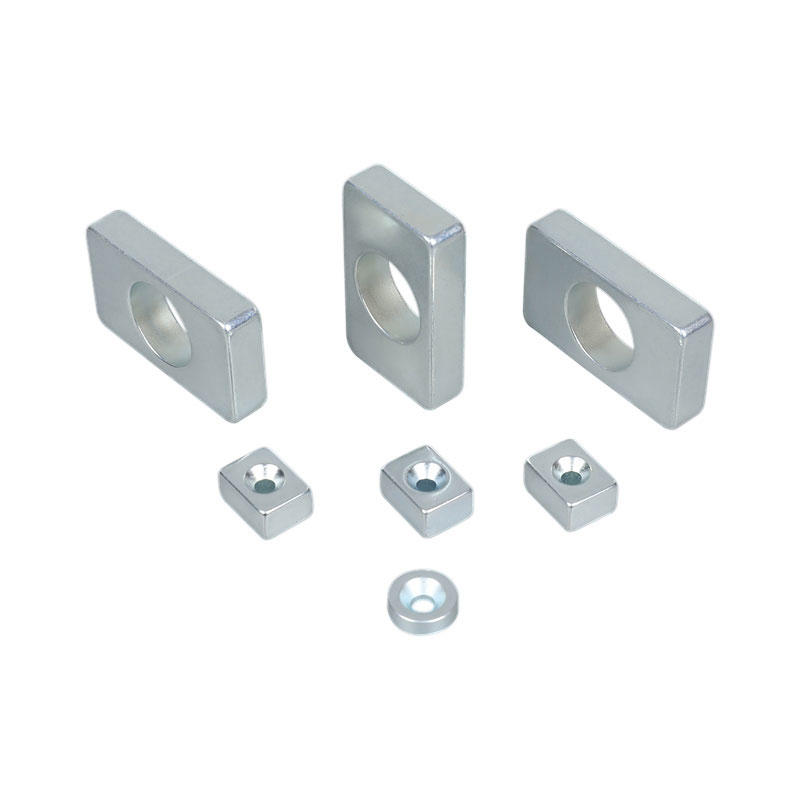

In car audio systems, NdFeB magnets are used in the form of a rectangular or cylindrical magnet. These magnets are used to provide strong magnetic field and stability for the speaker cone, which is essential for producing quality sound in a noisy environment. The rectangular magnet is used in mid-range and bass speakers, whereas the cylindrical magnet is used in tweeters. The advantage of using NdFeB magnets in car audio systems is that they offer excellent power-to-size ratio and produce high-quality sound with minimal distortion. However, the disadvantage is that they are expensive compared to other types of magnets.

We have in-depth cooperation with world-renowned brands Harman, ASK (car high-end audio), BOSE (top audio factory), Amazon's Guoguang, and Lianchuang Lisheng.

English

English Español

Español Deutsch

Deutsch Tiếng Việt

Tiếng Việt

+86-15857968349

+86-15857968349

WeChat/Zalo/whatsApp: +86-15857968349(Jerry Ma)

WeChat/Zalo/whatsApp: +86-15857968349(Jerry Ma)

Email: mahy@dymagnet.com

Email: mahy@dymagnet.com  No.9,Hongxing 3rd Road,Hengdian Industrial Park,Dongyang City,Zhejiang,China.

No.9,Hongxing 3rd Road,Hengdian Industrial Park,Dongyang City,Zhejiang,China.