Sintered NdFeB permanent magnet materials belong to the third generation of rare earth permanent magnet materials. They have the characteristics of strong magnetism, light weight, small size and high energy efficiency. They are key electronic materials for important components of contemporary manufacturing industries such as precision electroacoustic devices and rare earth permanent magnet motors.

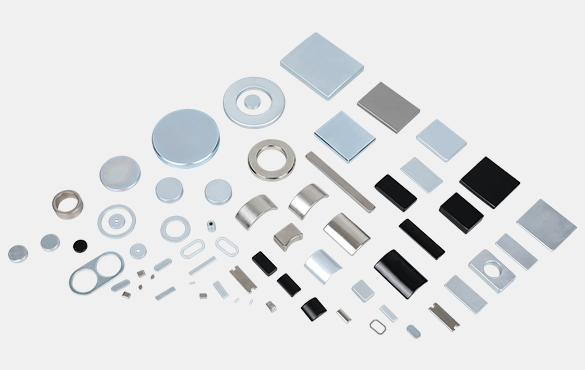

The performance of the sintered NdFeB permanent magnet materials currently produced by the company can meet the needs of the high-end market in many application fields. According to the intrinsic coercive force HCJ, it can be divided into N, M, H, SH, UH, EH, TH Seven series, forming a series of products with more than 70 grades, such as N33,N35M,N45UH,N52,N52UH,etc. Sintered NdFeB magnets are stronger and more durable than other types of magnets, but they also tend to be more expensive and brittle.

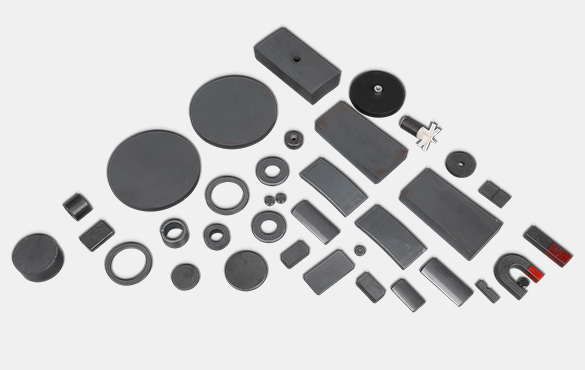

Permanent ferrite magnets usually refer to sintered permanent ferrite magnets, which belong to the second generation of permanent magnet materials. They have the characteristics of high resistivity, good stability, and strong resistance to environmental changes. It is a key electronic material for components such as electroacoustic devices and permanent magnet motors. The company currently produces 20 types of permanent ferrite magnets with complete specifications, forming a relatively complete product cluster, which can meet the diversified market demand in many application fields.

Zhejiang Zhongke Magnetic lndustry Co., Ltd. is famous ferrite permanent magnet manufacturers and Ferrite Magnet factory in China for many years. lts high-quality products include permanent sintered neodymium magnet and sintered ferrite magnet which is widely used in consumer electronics, energy-saving white appliances, new energy vehicles, etc. It owns more than 4000 items, mainly supplied to large and medium-scale customers at home and abroad, including SAMSUNG, amazon, Nidec, Xiaomi, GREE, Midea, WOLONG, etc.

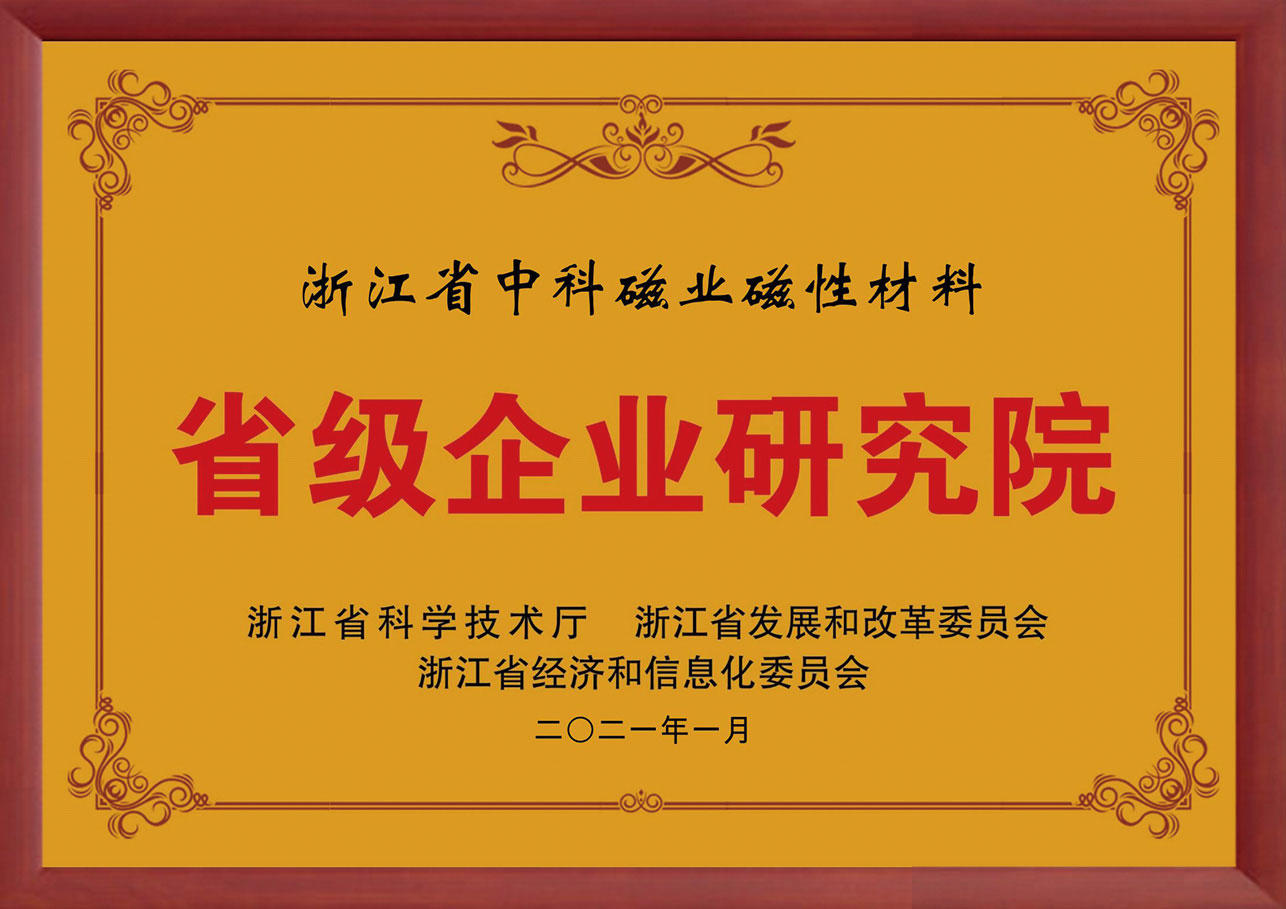

lt has two production bases, sintered Ferrite magnet factory and sintered NdFeB factory, which can guarantee fast delivery and high-quality. Zhongke has a strict quality system and has already passed ISO14001, ISO9001, TS16949, OHSAS 18001, ISO 45001. All products meet RoHS, REACH and have MSDS Certificate. Zhongke is a famous Brand in Zhejiang, a provincial high-tech R&D Center and an innovative Demonstration Enterprise in Zhejiang. Our main customers are leading manufacturers of electroacoustic devices and permanent magnet machine manufacturers in the industry.

1. Wear protective equipmentPersonal safety protection is crucial when dealing with strong magnetic neodymium ...

1、 Raw material preparation and proportioningIn the production process of neodymium iron boron block magnets, ...

From 22 to 25, Oct.,2024, it is reported that Zhejiang Zhongke Magnetic Industry Co., Ltd. will be participati...

1. Electric Motors and GeneratorsNeodymium ring magnets are fundamental in the design and operation of electri...

1. Magnetic Strength and StabilityPowerful ferrite speaker magnet are renowned for their impressive magnetic s...

1. StrengthMagnetic Force: The strength of Neodymium disc magnets directly affects their magnetic force. Magne...

Zhejiang Zhongke Magnetic Industry Co., Ltd is professional manufacturer and factory which produces magnets made from sintered ferrite material. We also offer custom ferrite magnet design services for customers who require specialized magnets for unique applications.

Sintered ferrite permanent magnets, also known as ceramic magnets, are a type of permanent magnet made from a mixture of iron oxide (Fe2O3) and barium or strontium carbonate (BaCO3 or SrCO3). Zhongke Magnetic mixing the powder ingredients, molding the mixture into the desired shape, and then sintering it to create a solid, dense material. They are widely used due to their low cost, high stability, and strong magnetic properties.

Sintered ferrite magnets have a low maximum energy product (BHmax) compared to other types of permanent magnets, such as neodymium magnets. This means that they produce a weaker magnetic field for a given volume of material, which limits their use in high-performance applications. However, sintered ferrite magnets have high resistance to demagnetization and corrosion, making them a reliable choice for many common applications, such as white appliances and speaker, wind generator, etc.

High coercivity: Ferrite Magnets have high coercivity, meaning they are able to maintain their magnetism even in high temperatures or in the presence of demagnetizing forces.

Low cost: Ferrite Magnets are generally less expensive than other types of permanent magnets, such as neodymium or samarium cobalt magnets.

Wide range of shapes and sizes: Ferrite Magnets are available in a variety of shapes and sizes, making them suitable for a wide range of applications.

Good chemical stability: Ferrite Magnets are highly resistant to corrosion and do not require a coating to protect them from the environment.

Good resistance to demagnetization: Ferrite Magnets are able to resist demagnetization caused by external magnetic fields, making them suitable for use in motors, speakers, and other electromagnetic devices.

Versatile: Ferrite Magnets can be used in a wide variety of applications, including automotive, electronics, and industrial machinery.

Durable: Ferrite Magnets have a long lifespan and are highly resistant to environmental factors like temperature, humidity, and corrosion.

Strong magnetic performance: Ferrite Magnets provide strong magnetic performance for their size and cost, making them an excellent value for customers looking for affordable magnetic solutions.

Energy efficient: Ferrite Magnets require less energy to magnetize or demagnetize compared to other types of magnets, making them a good choice for energy-efficient applications.

Safe: Ferrite Magnets do not pose the same safety hazards as other types of magnets, such as neodymium magnets, which can be very strong and may cause injury if mishandled.