Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

NdFeB (Neodymium Iron Boron) magnets are widely used in the field of sensor technology due to their excellent magnetic properties. These magnets are composed of a combination of neodymium, iron, and boron, which results in high magnetic strength and superior performance compared to other magnet materials.

+86-15857968349

+86-15857968349

Application Fields:

Magnetic Sensors: NdFeB magnets are extensively used in various magnetic sensor applications. They are employed in speed sensors, position sensors, proximity sensors, and magnetic switches, among others. These magnets provide precise and reliable detection of magnetic fields.

Magnetic Separators: NdFeB magnets are utilized in magnetic separators to separate and remove magnetic particles from different materials. We find applications in industries such as mining, recycling, and food processing.

Magnetic Resonance Imaging (MRI): NdFeB magnets are used in MRI machines to generate a strong magnetic field. This field interacts with the body's hydrogen atoms, allowing for detailed imaging of internal body structures.

Don't worry if you don't know which magnet you need for your motor project. Just tell us your applied industry, product performance parameters, size and quantity, we will recommend the most suitable product for you with our rich experience.

With a strong engineer team and professional production lines, Zhongke can design and produce magnet in all shapes according to your needs.

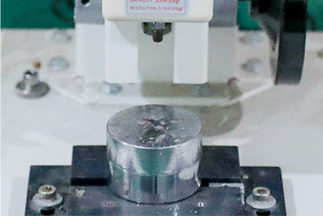

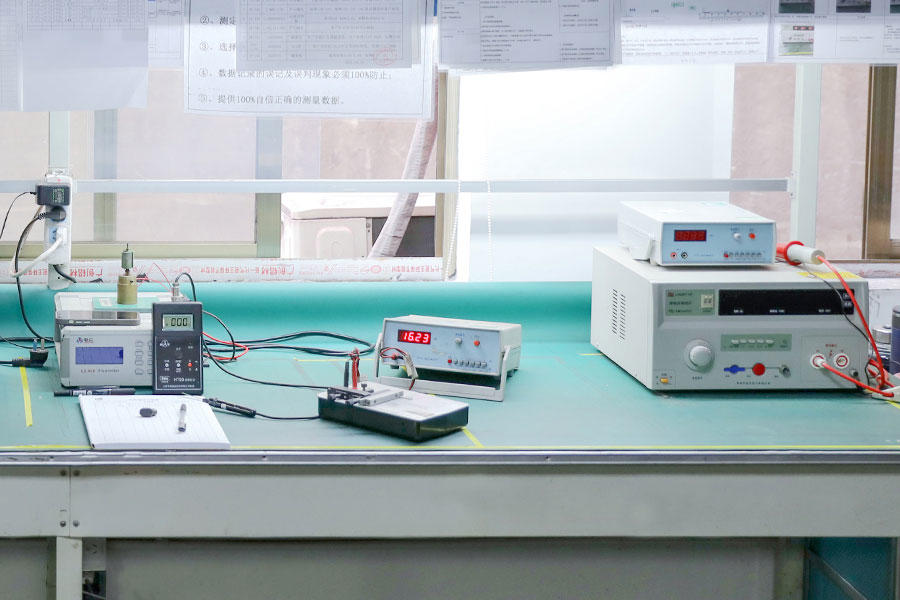

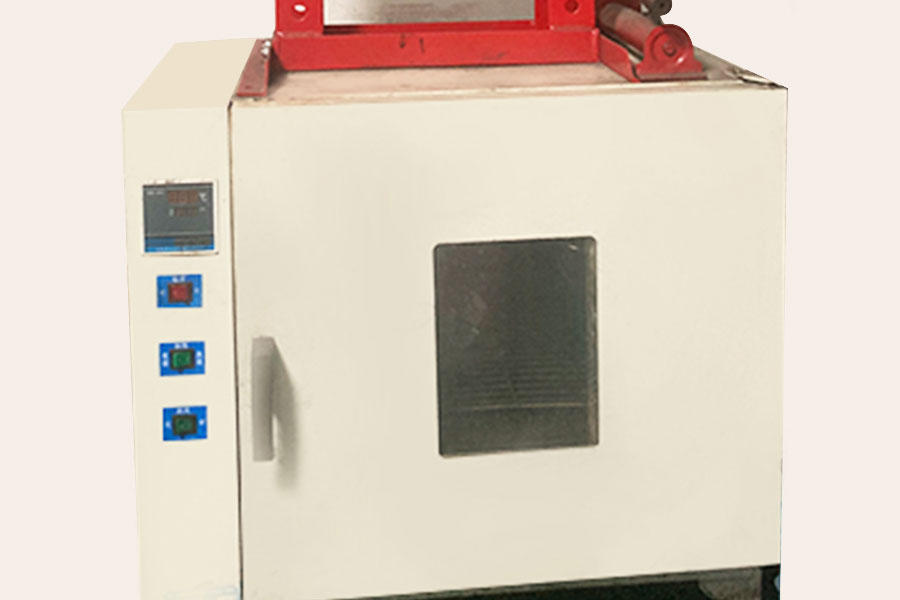

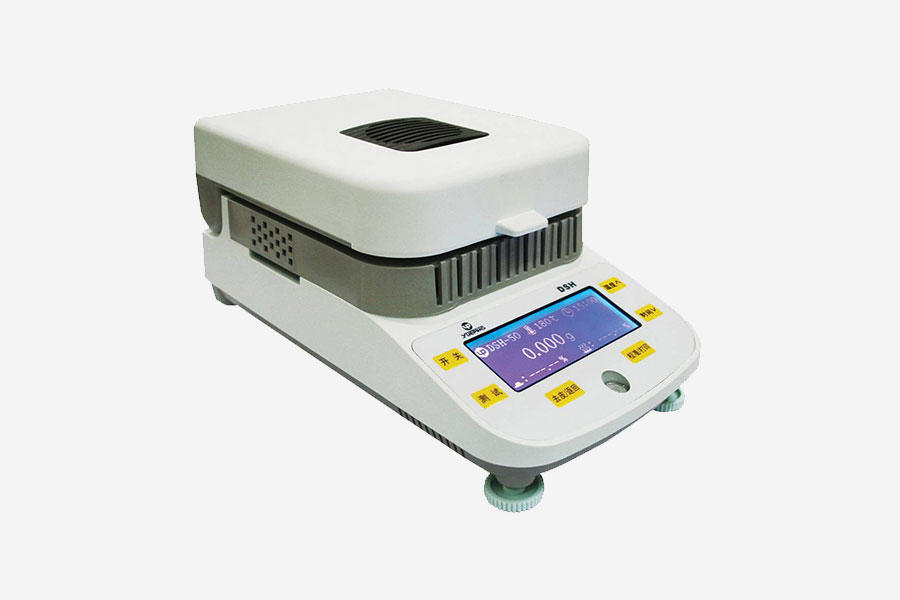

If you are not sure about the performance parameters of the product, you can send us a sample, we will do a professional test, determine the performance parameters and issue a report for your reference.

Exclusive customer service 7x24 hours to get professional help, make an appointment with a professional technical engineer to get a comprehensive solution.

Publicly traded listed magnet company in China. Our magnet supplied to many large, medium-scale customers including SAMSUNG, Nidec, Xiaomi, GREE, Midea, WOLONG, amazon, etc. We manufacture type of Ferrite Magnet and Neodymium(NdFeB) Magnet for electric motor, widely used in the field of new generation consumer electronics and energy-saving home appliances.

Just tell us your applied industry, product performance parameters, quantity and size, we will recommend the most suitable magnet for you.

Requirements for Magnet Size, Performance, and Shape:

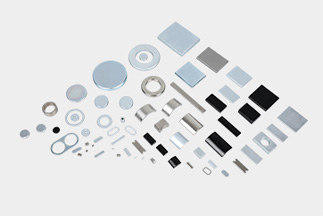

Size: The size of NdFeB sensor magnets depends on the specific application requirements. They can be customized to meet the desired dimensions, ranging from small micro magnets to larger block magnets.

Performance: NdFeB magnets offer high magnetic strength, excellent coercivity, and good temperature stability. The performance requirements depend on the specific application and operating conditions.

Shape: NdFeB magnets can be manufactured in various shapes, such as discs, cylinders, rings, blocks, and custom shapes. The shape is chosen based on the application requirements and magnetization direction.

Advantages of Zhejiang Zhongke Magnetic Co., Ltd. in Manufacturing:

Zhejiang Zhongke Magnetic Co., Ltd. is a leading manufacturer of NdFeB magnets and has several advantages in the manufacturing process:

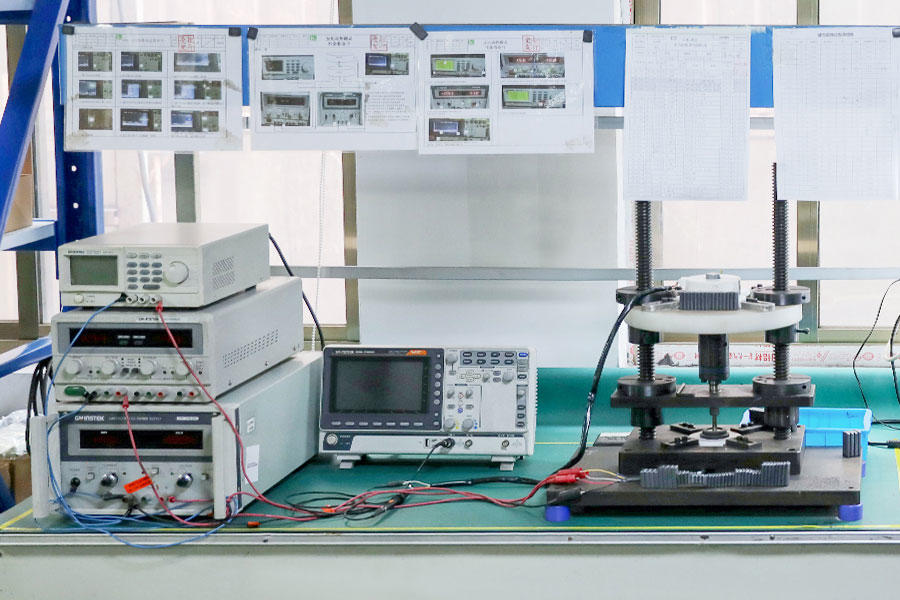

Advanced Production Facilities: Zhejiang Zhongke Magnetic Co., Ltd. has state-of-the-art production facilities equipped with advanced machinery and technology, ensuring high-quality magnet production.

Technical Expertise: Zhejiang Zhongke Magnetic Co., Ltd. has a team of experienced engineers and technicians who possess deep technical expertise in magnet manufacturing. We ensure precise magnet specifications and superior product performance.

Quality Control: Zhejiang Zhongke Magnetic Co., Ltd. follows strict quality control measures throughout the manufacturing process, ensuring consistent quality and reliability of the magnets.

Experience Advantage with Collaborative Customers:

Zhejiang Zhongke Magnetic Co., Ltd. has a strong track record of collaborating with various customers, providing them with high-quality NdFeB magnets for their specific applications. The experience advantage includes:

Customization: Zhejiang Zhongke Magnetic Co., Ltd. has the capability to customize NdFeB magnets according to customer requirements, ensuring optimal performance and fit for their applications.

Technical Support: Zhejiang Zhongke Magnetic Co., Ltd. offers technical support and assistance to its customers, helping them select the right magnet design and specifications for their applications.

Timely Delivery: Zhejiang Zhongke Magnetic Co., Ltd. has a reliable and efficient production and delivery system, ensuring on-time delivery of magnets to customers.

Analysis of Global Market Prospects:

The global market prospects for NdFeB sensor magnets are promising. The increasing demand for sensors in various industries, such as automotive, electronics, and healthcare, is driving the growth of the market. Additionally, advancements in sensor technology and the need for high-performance magnets contribute to the market's expansion.

FAQs And Answers:

Q1. What is the maximum operating temperature of NdFeB sensor magnets?

A1. The maximum operating temperature of NdFeB magnets depends on the grade. Generally, it ranges from 80°C to 220°C.

Q2. Can NdFeB magnets be coated for protection?

A2. Yes, NdFeB magnets can be coated with materials like nickel, zinc, epoxy, or plastic for protection against corrosion and damage.

Q3. Are NdFeB magnets recyclable?

A3. Yes, NdFeB magnets are recyclable. The materials used in their composition can be reused in the production of new magnets.

Q4. Can NdFeB magnets lose their magnetism over time?

A4. NdFeB magnets have excellent magnetic stability and only experience minimal loss of magnetism over an extended period.

Q5. Are NdFeB magnets hazardous to health?

A5. NdFeB magnets are generally safe to handle. However, they are extremely strong magnets and should be handled with care to avoid injury or damage to electronic devices.

Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

The company's current production process of permanent ferrite magnets is as follows: the purchased pre-fired materials are mixed according to their own formula and ingredients, and after being ball milled by a ball mill, ferrite is produced through steps such as precipitation, wet pressing, sintering, and grinding. Body magnetic tiles, ferrite magnets and other finished products. The specific production process flow chart is as follows:

The strontium ferrite calcined material (the main component is SrFe12O19) is mixed with calcium carbonate, silicon dioxide, strontium carbonate, lanthanum oxide, cobalt oxide and other ingredients according to the formula ratio.

The raw materials are added with water and pulverized by a ball mill to form a slurry, which is placed in a sedimentation tower for precipitation.

The dehydrated material formed by precipitation is made into a green body through an automatic press in a normal air environment.

The raw body is sintered at high temperature into a mature body through a wet-pressed magnetic tile electric-fired roller kiln or a wet-pressed magnetic steel gas-fired roller kiln.

The cooked blank is processed by a fully automatic grinding machine processing line to form a finished product.

The magnetic properties, appearance, size and other indicators of the magnets are inspected, packed and put into storage.

The company has applied and improved a number of advanced technologies in the industry, such as high-performance ferrite slurry stabilization technology and secondary ball milling batching technology, which has solved the quantitative problem of material added in the preparation process. And we use double coupling dispersion and fine grinding to overcome the problems of slurry agglomeration and particle size distribution consistency. The performance of the slurry obtained in the ball milling process is more stable, which reduces the unit operating time of the ball milling equipment, improves product quality, and reduces production costs.

The company uses a unique new green release agent independently developed to prepare magnetic tiles. The new green release agent is an organic combination of microbial technology and surface release treatment technology, which can degrade oil molecules, reduce the oil content of the release agent, and restore the surface. active lipophilic factor. The product is combined with the surface release process, and the release effect of the magnetic tile is improved through a new release agent, and the surface finish of the blank is improved. The demoulding technology has the characteristics of simple preparation method and convenient application, and improves production efficiency.

By transforming the sintering preheating system equipment, the company reduces the water content of the sintered green body in the kiln, greatly reduces the waste rate caused by factors such as cracking and lack of oxygen during sintering, and improves the sintering density and mechanical strength of the product. Obtain good microstructure and magnet properties. The company has also realized the sintering base temperature that products with different performances can adapt to through formula adjustment. Products with different specifications, sizes and performances can be co-fired at the same temperature, which significantly improves the production efficiency of the sintering process. In addition, in terms of veneer loading and billet loading, the company has adopted a bulk stacking method that conforms to the company's product features of small shape and light weight after many tests, realizing heavy veneer loading, good sintering atmosphere, and high sintering yield. good effect.

By optimizing the parameters of grinding machines and other processing equipment and improving the process technology, the company has improved the consistency of product thickness to ≤0.02MM within L30MM and ≤0.04MM within L50MM, and has mastered the technology of three-phase motor magnets produced by grinding tooling. Breakthroughs have been made in technical difficulties in the industry, such as product precision and stable equipment performance, and certain innovations have been achieved in technology and equipment.

The company's magnetic tile products are developing in the direction of high efficiency, low consumables, and low energy consumption. For example, through atomic substitution and compound doping, the rare earth-free ZK-5B high-performance motor magnetic tile independently developed by the company reduces the coagulation of magnetic powder, improves the orientation effect, improves the material performance and reduces the production cost by using strong magnetic field to suppress and adding a double dispersant.