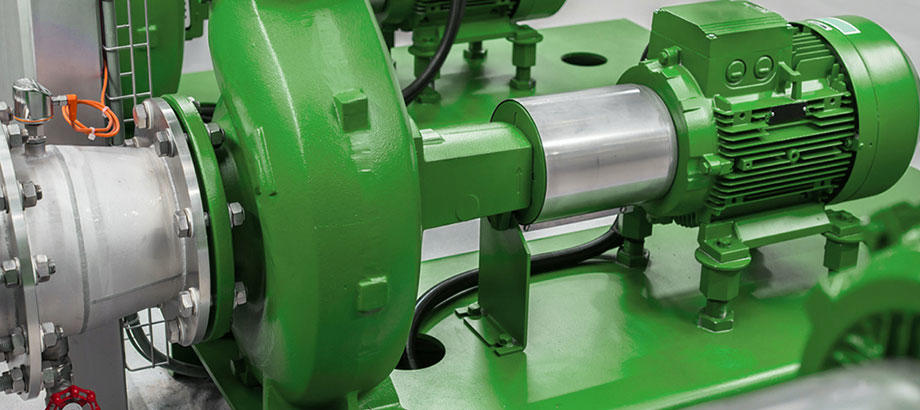

Industrial Equipment

Industrial motors refer to general equipment motors such as fans, water pumps, compressors and machine tools that are widely used in the industrial field. Industrial motors are the area with the largest power consumption in China. In 2020, China's motor population will be about 4 billion kilowatts, with a total power consumption of 4.8 trillion kilowatt hours, accounting for 64% of the total power consumption of the whole society, of which the total power consumption of industrial motors will be 3.84 trillion kilowatt hours.

With the official implementation of GB 18613-2020 Minimum Energy Efficiency Values and Energy Efficiency Grades of Electric Motors on June 1, 2021, the production of energy efficiency motors below IE3 (international standard) will be forced to stop. Limited by the basic working principle, the efficiency improvement of traditional asynchronous motors has a ceiling and is difficult. Therefore, some IE4 and IE5 grade energy efficiency motors are more inclined to use the permanent magnet mode, and permanent magnet direct drive of industrial motors will become the mainstream trend in the future.

On October 29, 2021, the Ministry of Industry and Information Technology and the State Administration of Market Supervision jointly formulated the Motor Energy Efficiency Improvement Plan (2021-2023). By 2023, the annual output of energy-efficient motors will reach 170 million kilowatts, and the proportion of energy-efficient motors in service will reach more than 20%. The annual power savings will be 49 billion kilowatt hours, equivalent to 15 million tons of standard coal saved and 28 million tons of carbon dioxide reduced. Promote the application of a number of key core materials, components and technological equipment, form a number of backbone competitive manufacturing enterprises, and promote the high-quality development of the motor industry. Guide enterprises to update and upgrade key energy consuming equipment such as motors, give priority to efficient and energy-saving motors, and accelerate the elimination of backward and inefficient motors that do not meet the requirements of the current national energy efficiency standards.

It is estimated that every 1% increase in energy efficiency of industrial motors can save about 38.4 billion kWh of electricity annually. At present, the penetration rate of rare earth permanent magnet motors in China is low, accounting for about 4%. Assuming that the penetration rate of rare earth permanent magnet motors in the new efficient energy-saving motors in 2023 is 100%, it is estimated that about 45000 tons of rare earth permanent magnet materials will be needed for 170 million kilowatts of efficient energy-saving motors. Therefore, with the accelerated elimination of backward and inefficient motors and the wide application of efficient and energy-saving motors, the demand for rare earth permanent magnet materials will have a larger growth space.