Zhongke is committed to becoming a world-renowned supplier of permanent magnet material application solutions in the field of new generation consumer electronics and energy-saving home appliances.

View Products

Consumer electronic products refer to intelligent electronic hardware products for consumers' daily life.

Household appliances refer to all kinds of electrical products that help or replace people to do housework or improve the living environment.

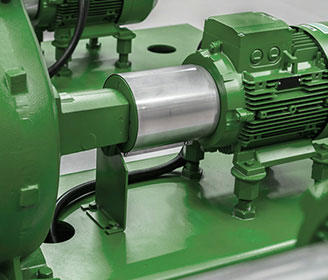

Industrial motors refer to general equipment motors such as fans, water pumps, compressors and machine tools that are widely used in the industrial field.

According to the data of Antaike, the global demand for high-performance iron masonry in 2018 is mainly concentrated in the field of automobile manufacturing.

At present, there are mainly two types of wind turbines: double-fed type and direct drive permanent magnet type.

The explosive expansion of China's industrial robot demand will continue to drive the development of the permanent magnet material industry.

Wind energy is a clean and sustainable resource, which belongs to a transformation form of solar energy. According to the analysis of the World Meteorological Organization and the Institute of Meteorological Sciences of the China Meteorological Administration, the available wind energy resources on the earth are 20 billion kW. Compared with traditional energy, wind energy has become one of the most widely developed and applied renewable energy and an important component of the development and utilization of renewable energy in the world. Its development is gradually changing from complementary energy to alternative energy, thanks to its huge reserves, no environmental costs such as carbon emissions, high degree of automation, no fuel price risk, and continuous reduction of electricity cost, Its application is an important driving force to promote energy structure optimization and energy low-carbon. In the context of the transformation of the global energy structure to low-carbon, China's encouragement of the development of the wind energy industry is of great positive significance for optimizing the energy structure, achieving carbon peak and carbon neutral, and improving the quality of economic development. The trend of sustainable growth of the wind energy industry is highly certain.

NdFeB (Neodymium Iron Boron) magnets have found wide applications in the field of wind power generation, particularly in the semi-direct and direct drive motors. These magnets are known for their high magnetic properties, excellent corrosion resistance, and low cost compared to other magnet materials.

Semi-direct drive wind turbines are designed with a gearbox in-between the blades and the generator. The gearbox is used to increase the rotational speed generated by the blades, enabling the generator to produce higher output power. NdFeB magnets are used in the direct drive generator to generate electricity in this system. The use of NdFeB magnets ensures that the generator is lightweight and compact while achieving high output power.

Direct drive wind turbines, on the other hand, have eliminated the need for a gearbox. This design simplifies the turbine assembly, reduces maintenance costs, increases efficiency, and extends the life of the turbine. The NdFeB magnets used in direct drive wind turbines are typically large in size but have the same magnetic properties as the smaller ones. In addition, with surface treatment such as Ni, Zn or epoxy coating, they resist corrosion and ensure long-term stability.

The performance grade of NdFeB magnets in wind turbines is dependent on their maximum energy product and their coercivity. Magnets with a higher maximum energy product generate more power while magnets with a high coercivity will maintain their magnetic strength for a long time. The maximum energy product of NdFeB magnets can be between 27 and 55 MGOe, and their coercivity can be between 10 and 30 kOe.

Surface electroplating is an essential process in the production of NdFeB magnets for use in wind turbines. This process is done to improve the surface properties of the magnet and enhance its corrosion resistance. The process typically involves coating the surface of the magnet with various metals such as nickel, zinc or epoxy. The thickness of the coating depends on the intended use of the magnet. The coating also serves as a barrier between the magnet and the surrounding environment, protecting it from humid or acidic conditions.

Zhejiang Zhongke Magnetic Industry Co., Ltd. is a leading manufacturer of NdFeB magnets in China. The company has advanced technology and equipment, a professional technical team, and strong production capacity. The plant is equipped with advanced manufacturing equipment such as vacuum melting furnaces, hot isostatic pressing machines, and automatic molding machines, which has enabled the company to produce high-quality NdFeB magnets for wind power generation.

Zhejiang Zhongke Magnetic Industry Co., Ltd. has a strong advantage in terms of product quality, reputation, and after-sales service. The company has obtained international certification such as RoHS and REACH, which further ensures the quality of the magnet products. The company also provides technical support to its clients, ensuring the efficient integration of the magnets into their products and systems.

In conclusion, NdFeB magnets have become essential components in wind power generation, particularly in semi-direct and direct drive motors. The magnets have high magnetic properties, excellent corrosion resistance, and are economical compared to other magnet materials. The performance grade of the magnets is determined by their maximum energy product and their coercivity. Moreover, surface electroplating treatments such as nickel, zinc or epoxy coating enhances the magnet's corrosion resistance, ensuring their long-term stability. Zhejiang Zhongke Magnetic Industry Co., Ltd. is a reliable manufacturer of NdFeB magnets and has advanced manufacturing technology, technical support, and excellent product quality.